Case Study: HAZOP-Led Welding Assurance for Oil & Gas Pressure Systems

Client

Confidential – Offshore Oil & Gas Operator

Project Overview

Carbon Arc was engaged to support the fabrication and qualification of pressure-retaining components for an offshore oil and gas installation. The project involved complex welding operations on high-integrity systems subject to ASME Section IX and the Pressure Equipment Directive (PED). Given the critical nature of the equipment, a HAZOP (Hazard and Operability Study) was integrated into the welding engineering scope to proactively identify and mitigate risks.

Our Role

Carbon Arc led the development and execution of a welding-focused HAZOP study, which was embedded into the broader engineering assurance framework. Key activities included:

Identifying potential deviations in welding processes using HAZOP guide words (e.g., “no weld,” “more heat,” “wrong filler”)

Evaluating risks associated with material selection, joint design, and environmental conditions

Reviewing welding procedure specifications (WPS) and qualifications (WPQR) for compliance and robustness

Assessing NDT protocols and inspection readiness

Documenting safeguards and corrective actions to ensure operability and safety

Execution & Oversight

Carbon Arc facilitated cross-disciplinary HAZOP workshops involving welding engineers, quality managers, and client representatives. The study focused on:

Aluminium and carbon steel weldments used in pressure systems

Process deviations that could lead to weld failure, distortion, or non-compliance

Inspection gaps in radiographic and ultrasonic testing

Operational risks such as delayed preheat, incorrect shielding gas, or post-weld heat treatment errors

Outcome

The HAZOP-led approach resulted in:

Early identification of critical welding risks

Enhanced documentation and traceability for regulatory audits

Improved weld quality and reduced rework

Successful certification of pressure systems under ASME IX and PED

Carbon Arc’s integration of HAZOP methodology into the welding engineering scope set a new benchmark for proactive risk management in oil and gas fabrication projects.

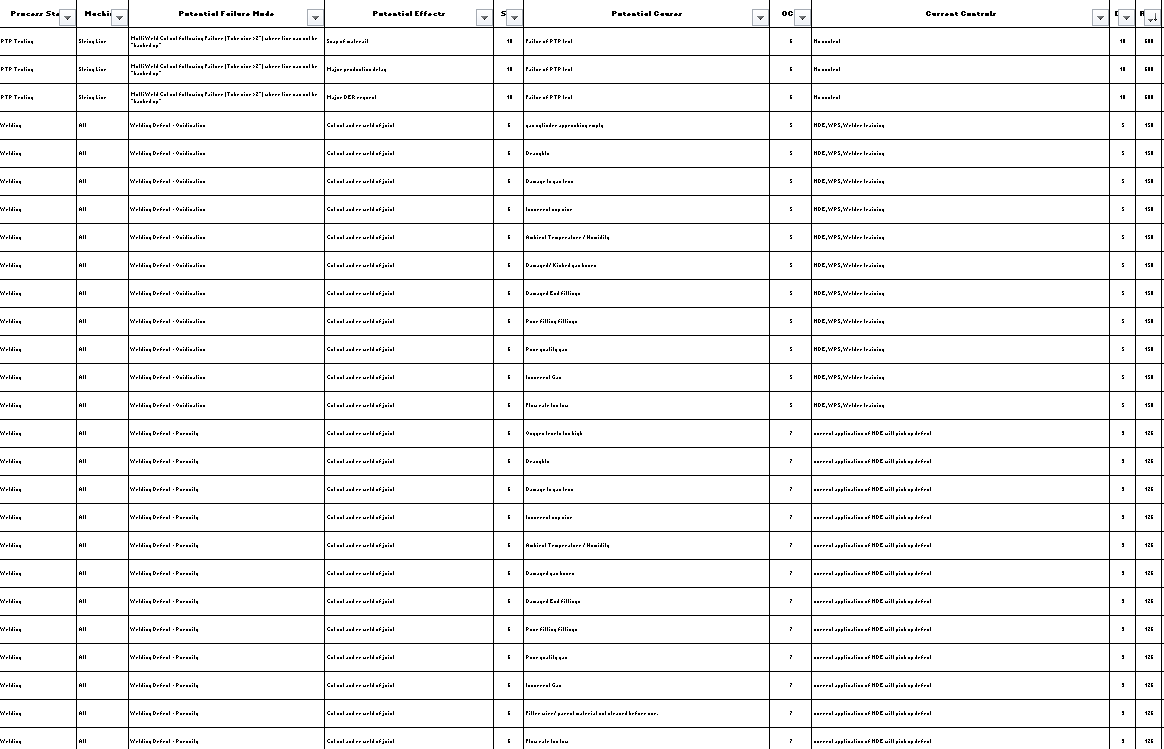

377 line FMECA matrix produced as part of the scope